| For beginners | ● Easy modeling and analysis settings |

|---|---|

| For advanced users |

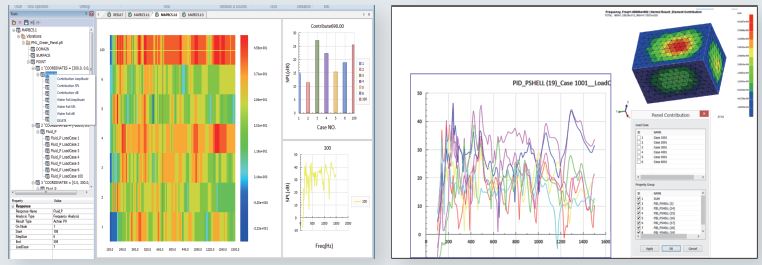

● Supports ultra-large-scale models ● High-precision, high-efficiency modeling ● Supports various analysis types according to the purpose ● 3D plot display such as waterfall ● Abundant sound energy flow display |

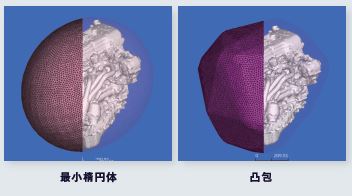

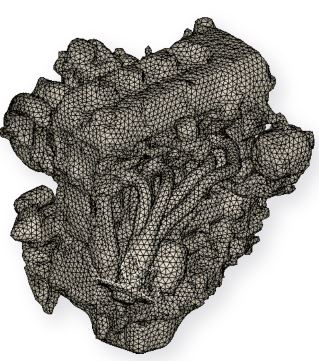

Jupiter-Pre system for structural analysis with abundant mesh editing functions for high-precision model creation.

It supports large meshes, so it maintains high performance even on engine models.

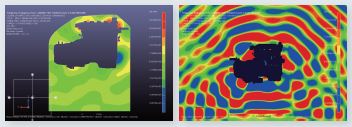

Jupiter-Post also has a cross-section display function that is convenient for checking the sound pressure distribution in the acoustic space.