|

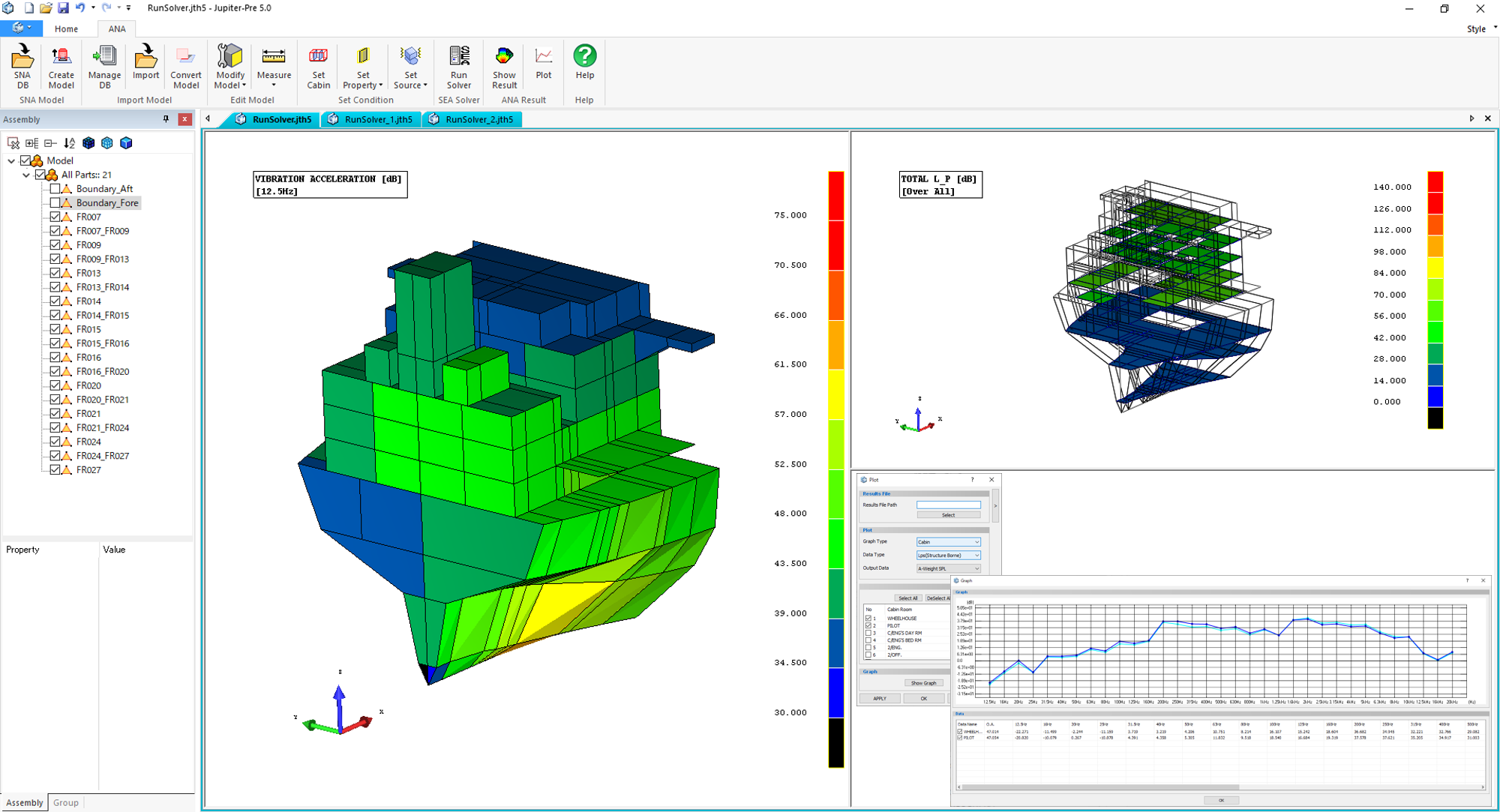

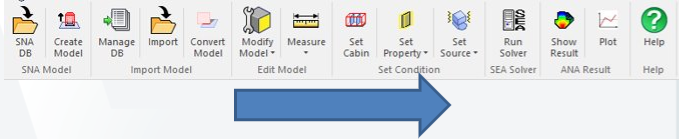

ANA is the most advanced version of our exisiting software SNA (Ship Noise Analysis). SNA has been jointly developed by Tokai University, Hakodate Dock, Sanoyas Shipbuilding, Tsuneishi Shipbuilding, Utsumi Shipbuilding, Odo Shipbuilding, Shinraijima Shipbuilding, Imabari Shipbuilding, Namura Shipbuilding, Sasebo Heavy Industries, Oshima Shipbuilding, Japan Maritime Association (titles omitted, in no particular order), and supported under the "Joint Research by Industry Request" scheme of the Japan Maritime Association. |