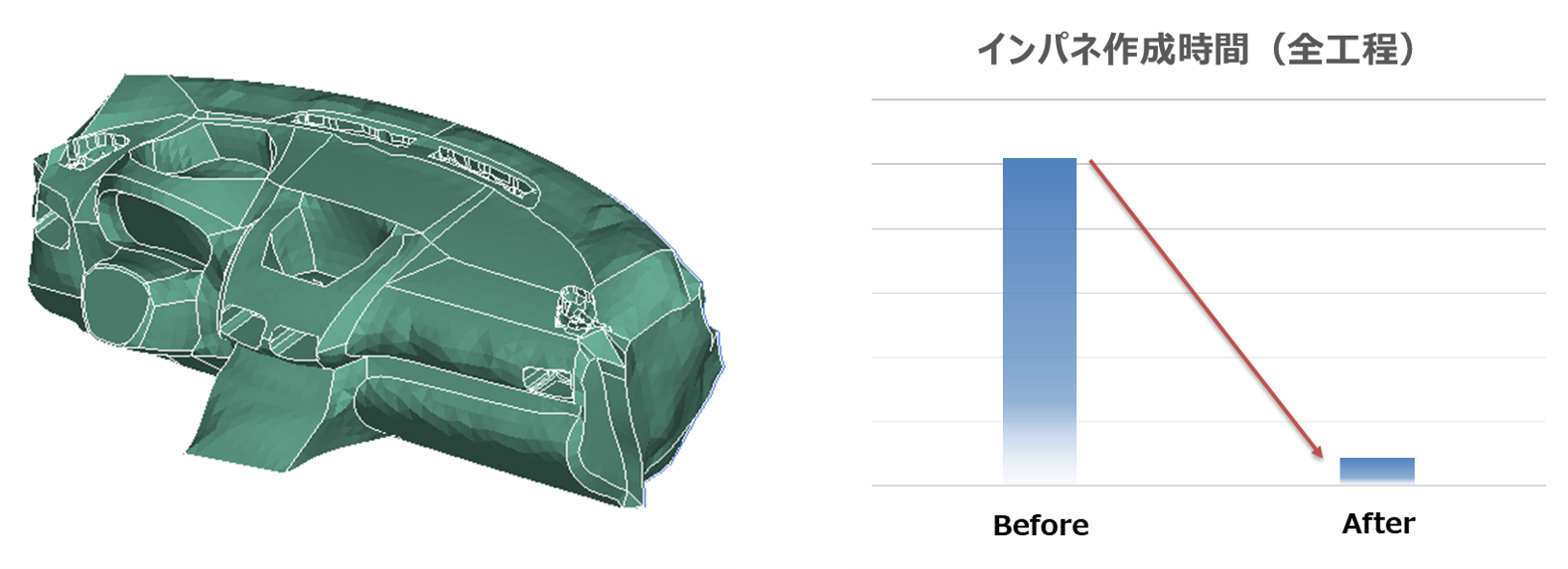

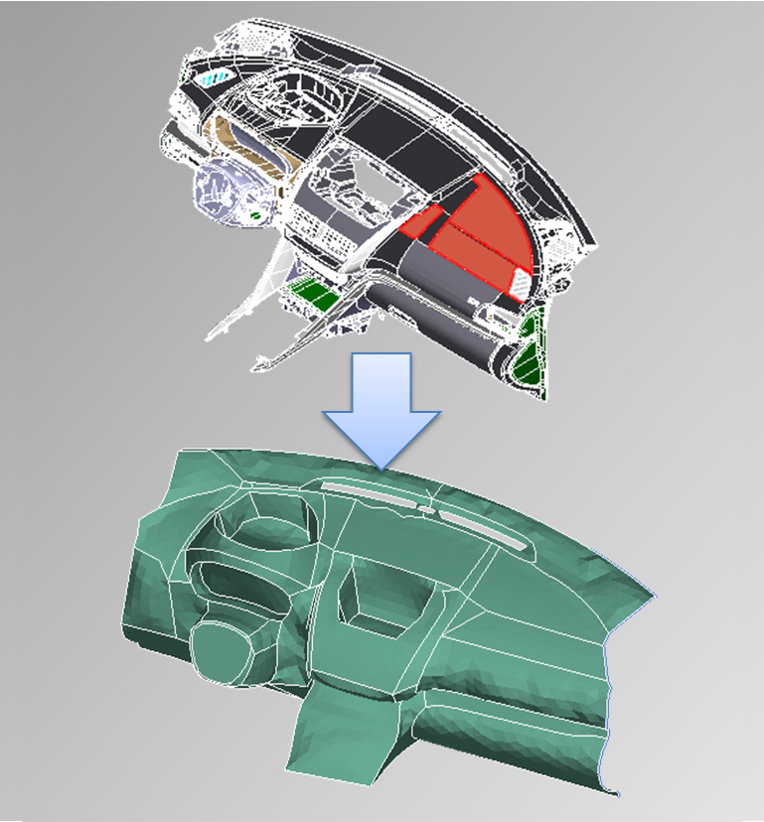

Structural analysis model / interior CAD model import

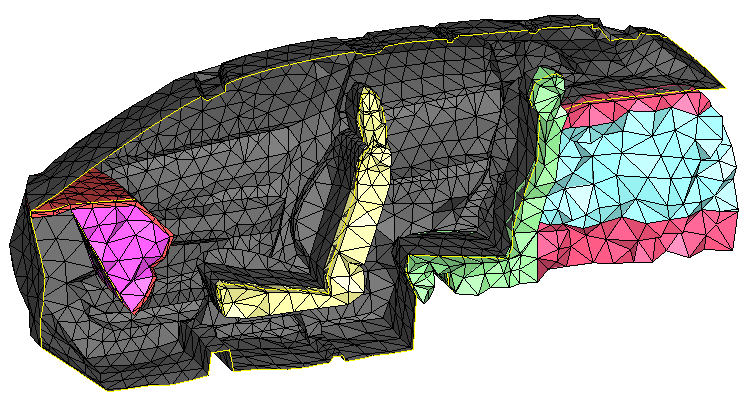

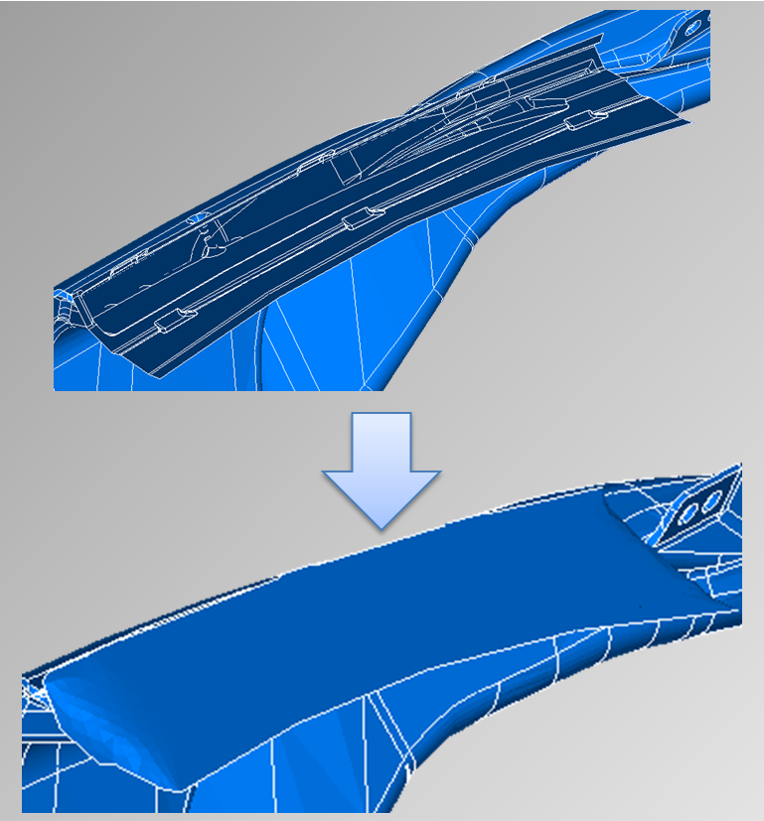

Create the interior / vehicle interior space surface mesh

Create the Car interior acoustic space solid mesh

ID adjustment of nodes/elements of the rigid body

Material / property setting bdf output