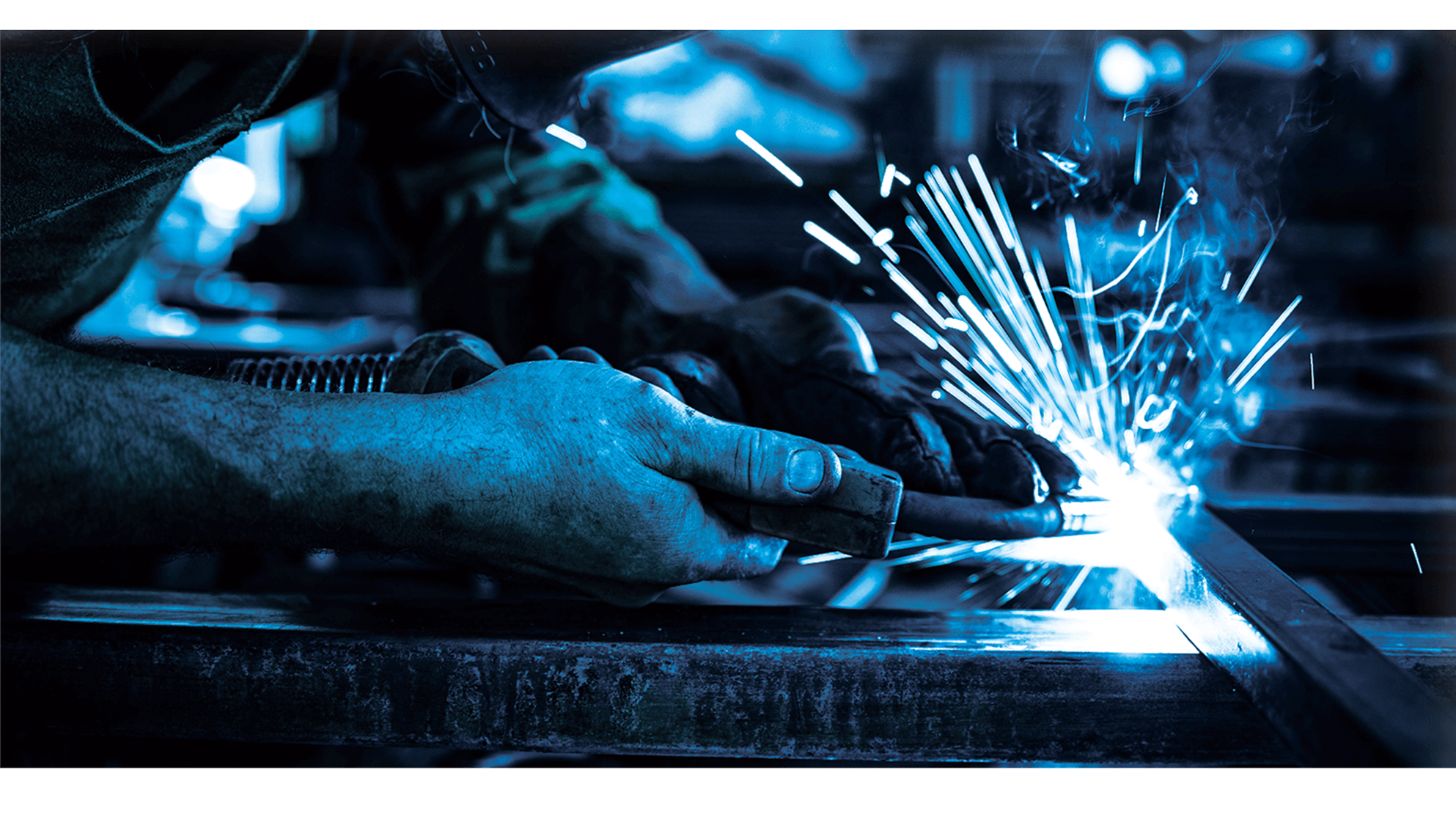

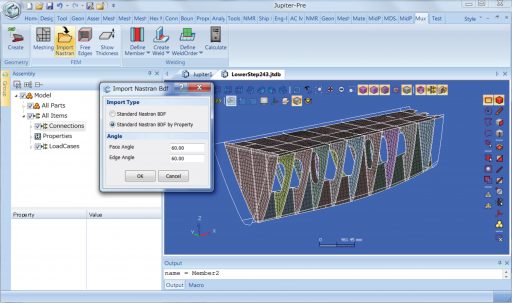

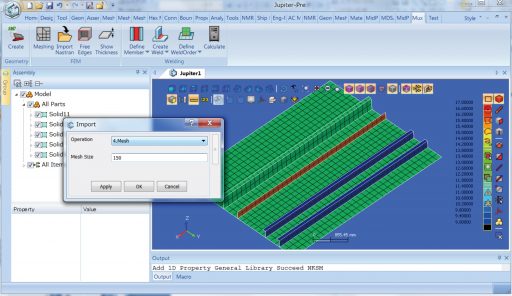

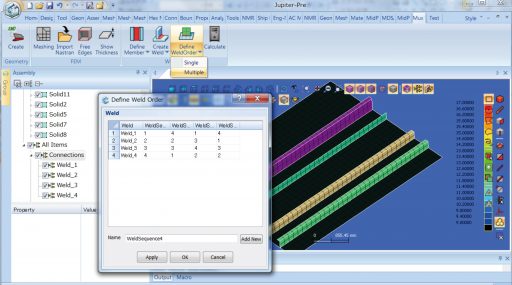

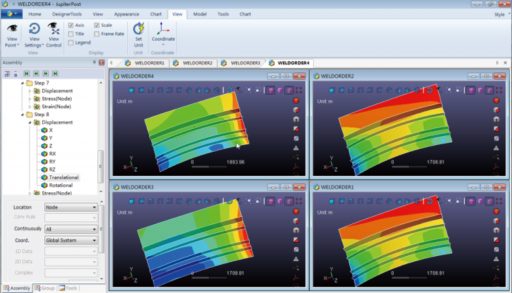

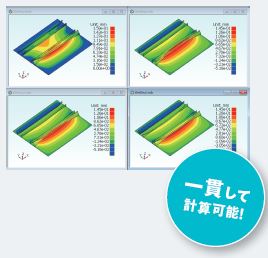

By porting JWRIAN from Osaka University to Jupiter-Platform, it is posible to consistently execute the mesh creation, welding condition setting, analysis execution, and result display with Jupiter.

| JWRIAN |

JWRIAN is a group of simulation software developed by CCWS of the Joining and Welding Research Institute at Osaka University for the purpose of analyzing mechanical phenomena related to welding. These softwares were developed mainly for the purpose of predicting weld deformation / residual stress and various weld cracks. |

|---|