There is a problem that it is difficult to quantitatively evaluate and generalize physical phenomena only by observing material tests, and it's difficult to elucidate the mechanism and build a physical model. Therefore, the quantitative evaluation of physical quantities by complicated analysis using CAE is required.

On the other hand, the particle method is not good at structural analysis (in terms of accuracy and stability due to the characteristics of the method), so this problem cannot be solved.

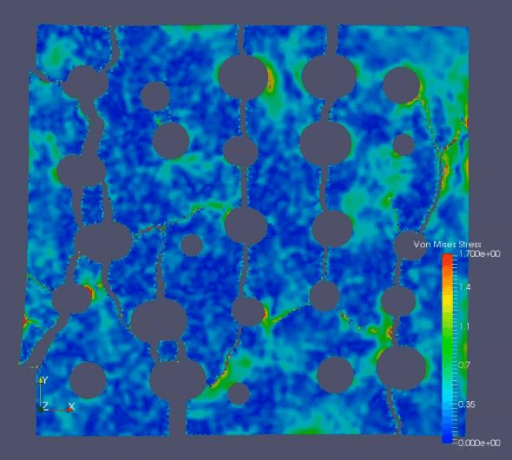

Peridynamics is a solid particle method suitable for structural analysis. By using Peridynamics, it is possible to simulate the complicated fracture phenomena that cannot be done by FEM or particle method.

Peridynamics is a type of particle method suitable for solid simulation.

The particle method is a modeling method of an object using only particles without using a mesh. There are many methods called the particle method, but the general particle method has been derived from continuum mechanics. Therefore, structural analysis has concerns about accuracy and stability, and has not been applied to actual problems.

Unlike the general particle method, Peridynamics is a method that combines molecular dynamics and continuum mechanics, and has the advantages of both. Since it can be applied to structural analysis, we are good at simulating complicated fracture phenomena.

| Analysis of FRP material | In a simple structure such as a cylinder such as an FRP crash box, the side wall bends inward and outward, and fiber breakage and laminate peeling proceed continuously (progressive crushing). This fracture phenomenon (delamination, fiber fracture, buckling, wedge formation, etc.) will be analyzed in details by Peridynamics Analysis. |

|---|---|

| Analysis of glass | Complex fracture forms are created due to the complexity of material properties and the internal scratches. It is necessary to pay attention to the fracture form itself from the viewpoint of safety when the glass is broken. Peridynamics enables detailed analysis of what kind of fracture process occurs and physical parameters that are difficult to observe in experiments. |